What does a brake tester do?

2024-10-11

A brake tester is a device used to assess the effectiveness and performance of a vehicle's braking system. It is commonly used in automotive workshops, vehicle inspection centers, and by fleet managers to ensure that a vehicle's brakes are functioning properly and safely. Brake testers are designed to simulate real-world braking conditions and measure various parameters related to brake efficiency.

Functions of a Brake Tester:

1. Brake Force Measurement:

- The brake tester measures the force applied by the brakes on each wheel during braking. This helps determine whether the brakes are applying sufficient force to stop the vehicle efficiently.

2. Brake Balance:

- It tests the balance between the brakes on the left and right sides of the vehicle. Uneven brake force can lead to dangerous situations, such as the vehicle pulling to one side during braking.

3. Pedal Pressure:

- Some brake testers can measure the pressure applied to the brake pedal, ensuring the hydraulic or pneumatic systems are working correctly and the driver is able to apply the required force for effective braking.

4. Deceleration Measurement:

- Brake testers can measure how quickly a vehicle slows down (decelerates) when the brakes are applied. This is a critical factor in evaluating braking performance.

5. Handbrake Testing:

- In addition to testing the main braking system, brake testers can evaluate the performance of the handbrake (or parking brake) to ensure it can hold the vehicle stationary on inclines.

6. Rolling Resistance and Brake Drag:

- Some brake testers can detect if the brakes are dragging (not fully releasing after braking), which can lead to reduced fuel efficiency and increased wear on the braking system.

Types of Brake Testers:

1. Roller Brake Tester:

- This type of brake tester uses rollers to simulate road conditions. The vehicle is driven onto the rollers, and as the wheels rotate, the brakes are applied. The tester measures the force exerted by the brakes and provides a detailed analysis.

2. Decelerometer (Road Brake Tester):

- A decelerometer is placed inside the vehicle and measures how quickly the vehicle decelerates during a road test. It is often used for heavy vehicles or vehicles with specialized brakes that cannot be tested on roller systems.

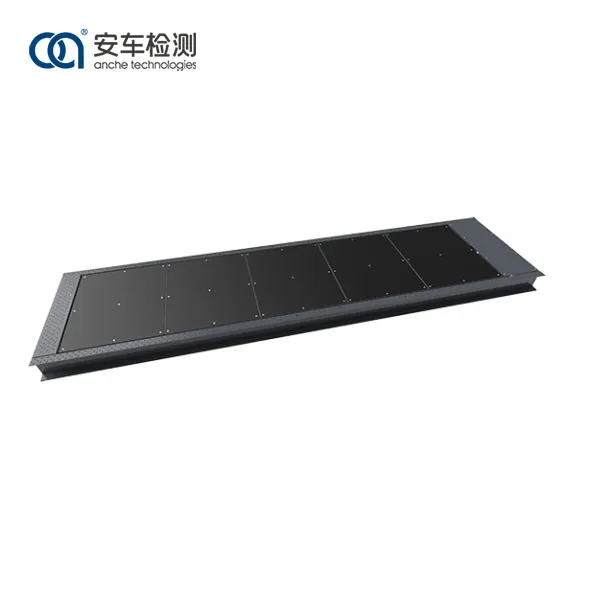

3. Plate Brake Tester:

- The vehicle drives over a plate that measures the braking force applied by each wheel when the brakes are engaged. This type of tester is typically used for lighter vehicles.

4. Pedal Force Tester:

- This tester specifically measures the force applied to the brake pedal by the driver. It is often used to ensure that the driver can apply the necessary force for effective braking.

Why Use a Brake Tester?

- Safety: Ensures the vehicle's brakes are functioning correctly, preventing accidents.

- Compliance: Many regions require periodic brake testing as part of vehicle inspections to ensure roadworthiness.

- Maintenance: Helps identify brake wear, malfunction, or imbalance early, reducing the risk of brake failure.

- Fleet Management: For businesses operating large fleets, regular brake testing ensures vehicle safety and reduces downtime due to brake-related issues.

In summary, brake testers are essential tools for diagnosing the performance and safety of a vehicle’s braking system, ensuring it meets legal and safety standards.